HI2931B/5 – AmpHel ORP Industrial Electrode

฿0.00

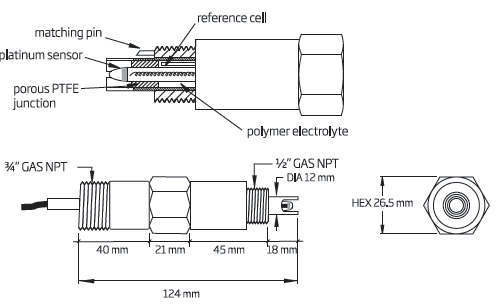

AmpHel ORP electrode with platinum pin, PTFE junction and 5 m cable.

Out of stock

AmpHel ORP electrode with platinum pin, PTFE junction and 5 m cable.

- Strong signal up to 75 meters (246’)

- Low noise coaxial cables are no longer required

- Measurements in unclean samples and high humidity conditions

- Models with external replaceable battery, for longer electrode life

- Glass sensor for specific applications

Due to the high resistance of the glass membrane, conventional electrodes require a high impedance measurement system. Inadequate insulation of the connectors and cables result in erroneous readings due to leakage or noise. For conventional electrodes, the lead is therefore limited to typically less than 15-20 meters. HANNA AmpHel® electrodes incorporate a miniaturized amplifier which resolves most of the problems associated with high impedance signals. The amplifier circuitry is located right on top of the electrode and is completely sealed. As a result, a strong, low impedance signal is emitted and ordinary connectors with long unshielded cables can be used. This breakthrough technology provides a stable signal for industrial monitoring as well as a major saving in low noise coaxial cable costs. In some cases, the need for a transmitter is also eliminated, resulting in further cost reductions.

For those applications that have been proven particularly hostile to electrodes, HANNA has developed four types of specialized glass. First is an extremely durable sensor glass for general purpose and industrial use. This glass can withstand the stress of daily use. The remaining types of electrode glass allow continuous monitoring in highly acidic solutions containing fluoride ions, as well as high or low temperature process streams, without significantly reducing the useful life of the electrode.

Electrode body material is glass or PEI, while the junction is cloth or PTFE.

Specification :

| Body | PEI | |

| Junction | PTFE | |

| Electrolyte | gel | |

| Glass Type | platinum | |

| Temperature | -5 to 80°C | |

| Max Pressure | 3 bar (43.5 psi) | |

| Connection | BNC | |

| Cable | 5 m | |

| Battery | internal |

| Weight | 0.000 kg |

|---|

Related products

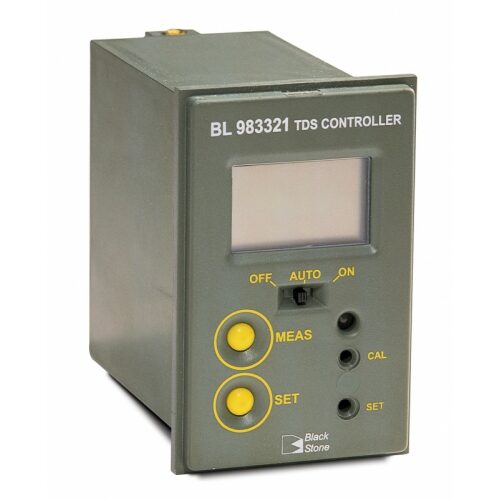

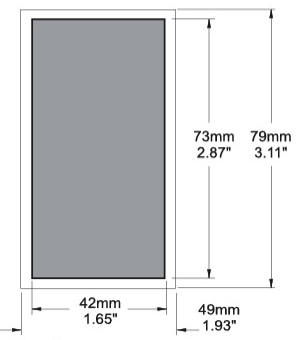

Blackstone BL983321-1 TDS (total dissolved solids) mini controller, 0.00 to 19.99 mg / L, 115/230V. Water treatment, heating and air conditioning systems, cooling towers, surface technology, light industrial processes

Blackstone BL931700-1 Mini pH Controller, dosage of acid or base, 4-20 mA recorder output, 115/230 V Water treatment, sewage treatment, neutralization and decontamination, surface treatment, simple industrial processes

All Product

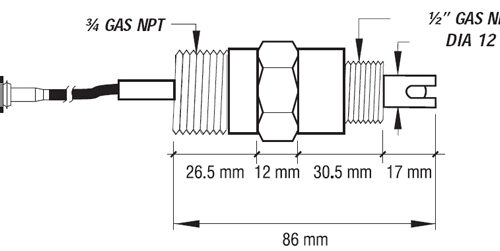

Flow-thru monitoring ORP electrode, platinum sensor, with BNC connection and 3 m cable.

Blackstone BL983317-1 Mini Conductivity Controller by 10.00 mS / cm, 115/230V. Dosing Relay - closes the contact when measured value

Blackstone BL932700-1 ORP mini controller, -1000 to +1000 mV, 4-20 mA recorder output, 115/230 V

All Product

Flow-thru monitoring ORP electrode with BNC connection and 3 m cable.

All Product

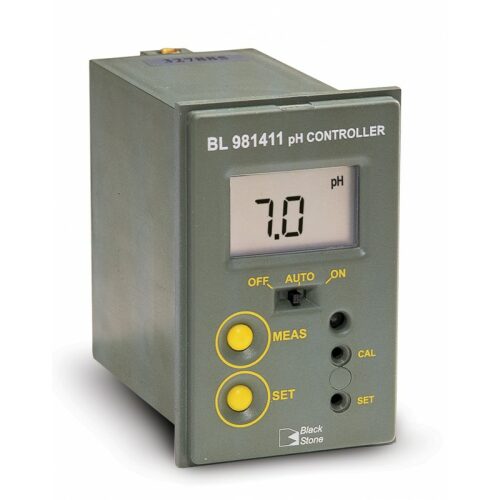

Blackstone BL981411-1 Mini pH Controller, dosage of acid or base, Resolution 0.1pH, 115/230V

Blackstone BL983327-1 Mini Conductivity Controller by 10.00 mS / cm, 115/230V. Dosing Relay - closes the contact when measured value> limit.