Subtotal: ฿13,270.14

Dual-Channel Universal Process Controller for Industrial – HI520 Series

Dual-Channel Universal Process Controller for Industrial – HI520

HI520 is an advanced process controller that can be configured for applications requiring monitoring and/or control of four main water-analysis parameters: pH, ORP, Conductivity, and Dissolved Oxygen.

– Waterproof IP65 (Nema 4X) enclosure

– Multi-color LED status indicators & audible alarm

– Universal mounting kits available with wall, pipe, and panel mounting options (All mounting kits must be ordered separately.)

HI520 is an advanced process controller that can be configured for applications requiring monitoring and/or control of four main water-analysis parameters: pH, ORP, Conductivity, and Dissolved Oxygen. This controller features a digital probe input(s) that automatically detects and updates the controller with the parameter that it measures.

HI520 is Hanna’s first dual-input process controller that accepts virtually any combination of compatible probes. Designed to adapt to unique process control requirements, users have the option to enable or disable each channel independently.

Additionally, HI520 introduces enhanced industrial control by operating a control-loop system whereby users have the option to run channel control either independently or configure to be triggered sequentially upon reaching the other channel’s set point(s) (1, 2, or both). The device operates a logical channel with built-in mathematical functions. This function is intended for when the controller works as an analyzer for monitoring high/low parameter levels between two identical inputs with identical measuring configurations.

Set points for control operations can be configured to be on/off, proportional, or PID types of control. The flexibility in programming allows for fine-tuning of a set point to be maintained with tight control preventing any overshoot and waste of chemicals.

Hold can also be triggered manually and by using and external digital input for disabling control mode when performing maintenance.

Configurable for set points and temperature or activated by abnormal operation, a red Alarm LED will blink and can easily be seen from a distance. All relays configured for control are inactivated until the alarm state is resolved.

The cleaning function allows the ability to program one or more wash cycles and use the relays to activate valves, pumps or compressed air based on the type of washing that is required to maintain probes for reliable results.

Relays

Available with up to five control and one alarm electromechanical relays.

Analog Outputs

Up to four galvanically isolated analog outputs for control of pumps and valves.

Digital RS485 Output

Can daisy-chain up to 32 devices to a remote monitoring system.

Digital Inputs

Two digital inputs available for modes including disabling, cleaning and placing the controller into hold status.

Manual : Downloads

Specification :

| SKU | HI520 |

| Product Name | Dual-Channel Universal Process Controller for Industrial Applications – HI520 |

| Channels | 2 |

| Display | Graphic LCD, 128 x 64 pixel B/W with backlight |

| Digital Inputs | 2 independent, galvanically isolated inputs (configurable for Hold & Cleaning functions) |

| On state | 5 to 24 Vdc, low or high level active |

| Analog Outputs | 2 or 4 independent, galvanically isolated outputs 0 – 22 mA configurable as |

| Digital Communication | RS485 serial port – Remote monitoring and control USB-C port – Retrieve log files and firmware upgrading |

| Relays | Up to 5 relays (independently configurable for process variables, Hold & Cleaning functions |

| Fuse protected | 5A, 250V slow blow fuse |

| Alarm Relay for All Measurement Alarms | Electromechanical relay SPDT contact output 5A – 250 Vac; 5A – 30 Vdc (resistive load) Fuse protected |

| Data Logging | Interval log, up to 100 files, maximum 8600 records on each stored file. When the maximum limit of 100 stored files is reached, the most recent file will automatically erase the oldest one. |

| Power Supply | 100 – 240 Vac ±10%; 50/60 Hz; 15VA; fuse protected (2A, 250V slow blow fuse) |

| Power Consumption | 15VA |

| Installation Category | II |

| Environment | -20 to 50 ºC (-4 to 122 ºF); maximum 100% RH non-condensing |

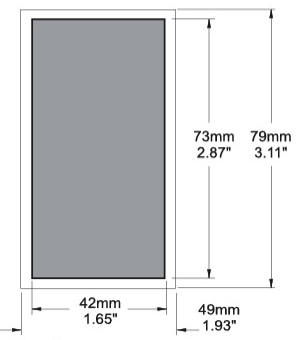

| Enclosure* | Single case ½ DIN, type 4X, IP65 ingress protection |

| Weight | Approximately 1.6 kg |

| Weight | 1.8 kg |

|---|---|

| Dimensions | 14.4 × 14.4 × 15.13 cm |

Related products

Blackstone BL983315-1 TDS (total dissolved solids) mini controller, 0.0 to 199.9 mg / L, 115/230V. Water treatment, heating and air conditioning systems, cooling towers, surface technology, light industrial processes

All Product

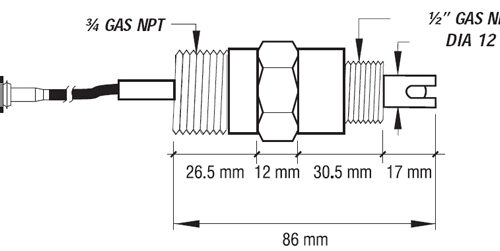

Flow-thru monitoring ORP electrode with BNC connection and 3 m cable.

All Product

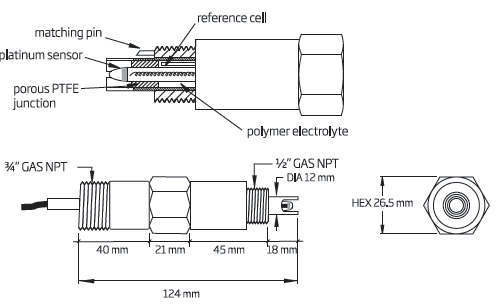

Flow-thru monitoring ORP, platinum sensor, electrode with matching pin and 5 m cable

Blackstone BL983314-1 resistance mini-controller, 0.00 to 19.90 MΩ / cm, 115/230 V Water treatment, heating and air conditioning systems, cooling towers, surface technology, light industrial processes

All Product

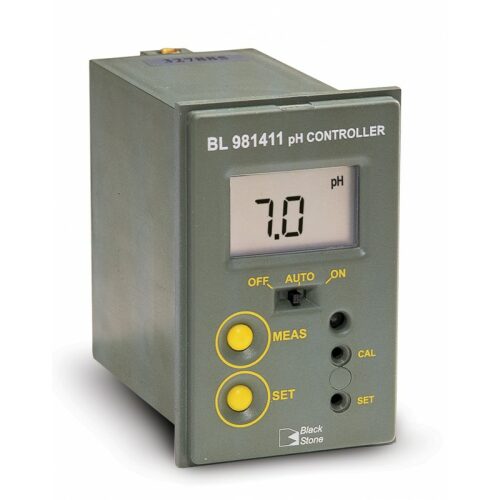

Blackstone BL981411-1 Mini pH Controller, dosage of acid or base, Resolution 0.1pH, 115/230V

Blackstone BL983320-1 Mini Conductivity Controller, 0 to 199.9 uS / cm, 115/230 V Water treatment, heating and air conditioning systems, cooling towers, surface technology, Simple industrial processes

Blackstone BL983324-1 TDS (total dissolved solids) mini controller, 0.0 to 49.9 mg / L, 115/230V. Water treatment, heating and air conditioning systems, cooling towers, surface technology, light industrial processes

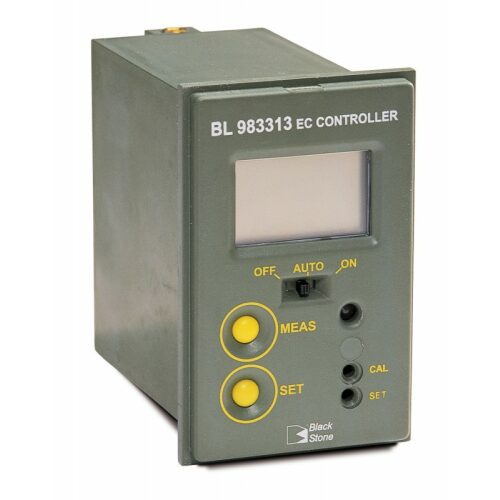

Blackstone BL983313-1 Mini Conductivity Controller, 0 to 1999 ĩS / cm, 115/230 V Water treatment, heating and air conditioning systems, cooling towers, surface technology, Simple industrial processes

เครื่องวัดปริมาณฟอสฟอรัส ช่วงสูง รุ่น HI706

เครื่องวัดปริมาณฟอสฟอรัส ช่วงสูง รุ่น HI706  HI2001 - ORP Electrode Process

HI2001 - ORP Electrode Process